SURFACE

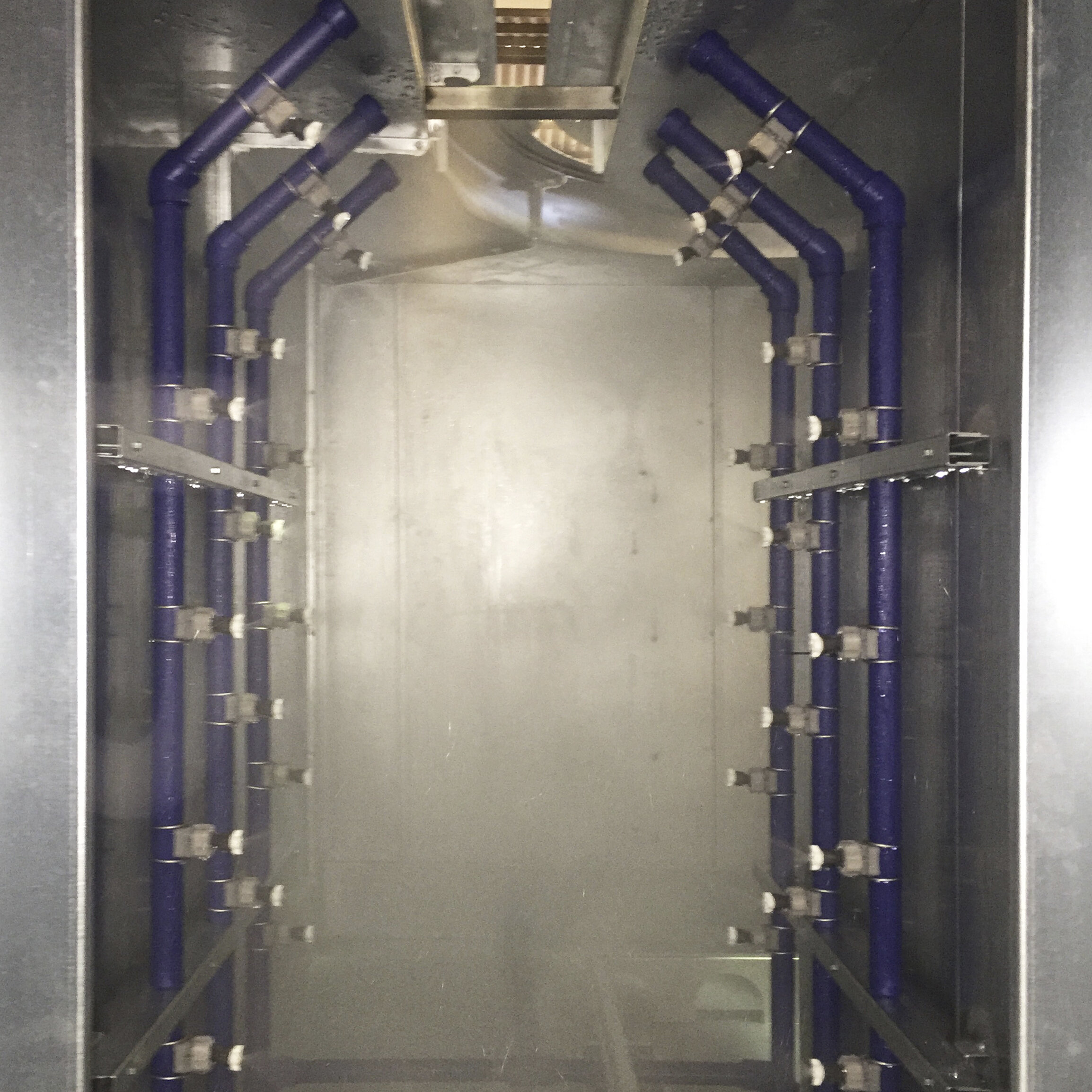

PRE-TREATMENT TUNNEL

In any painting operation it is fundamental to fully remove all oils, grease, dirt and oxides that are in the surface to be painted.

The process begins with one or several stages of industrial or demineralised/osmotized, degreasing washing, followed by deoxidation of the surface and the stage of anticorrosive treatment, which can be a chromate treatment for aluminium materials or phosphate treatment for steel material. Besides protecting the metal, these treatments also increase adherence of the paint to the substrate.

Recently, new nano-technological processes based in zirconium and silanes have been developed to eliminate the use of hexavalent chromium.

Each treatment solution is designed according to the customer’s requirements and in conjunction with the chemical supplier, in order to achieve optimal bath parameters.

We design our tunnels according to the latest demands in the market, not only applying the latest technologies but also allying good environmental practices.